Supplier / Exporter

Industrial Gasket Exporter in Gujarat

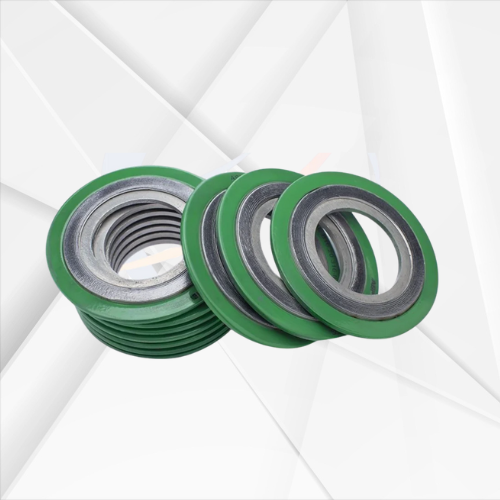

Spiral Wound Gasket

Key Features of Spiral Wound Gaskets

| Feature | Description |

|---|---|

| High-Performance Construction | Made from stainless steel windings with PTFE, graphite, or mica fillers for optimal sealing strength. |

| Pressure & Temperature Resistance | Withstands extreme operating conditions in both static and dynamic environments. |

| Reliable Sealing | Provides excellent resilience and recovery to maintain a leak-proof joint under varying loads. |

| Standard Compliance | Manufactured in accordance with ASME B16.20, API 601, and DIN specifications. |

| Industrial Applications | Ideal for oil & gas, petrochemical, power generation, and refinery systems. |

Viton Rubber Gasket

Key Features of Viton Rubber Gaskets

| Feature | Description |

|---|---|

| High-Grade Material | Made from 100% genuine Viton (FKM) rubber offering superior resistance to oils, fuels, and solvents. |

| Temperature Resistance | Performs reliably in extreme temperature ranges from -20°C to +200°C. |

| Chemical Compatibility | Excellent resistance to acids, hydrocarbons, and aggressive chemicals. |

| Durable & Leak-Proof | Provides long-lasting, tight sealing with excellent compression and recovery properties. |

| Industrial Applications | Widely used in oil & gas, petrochemical, chemical, and automotive sectors. |

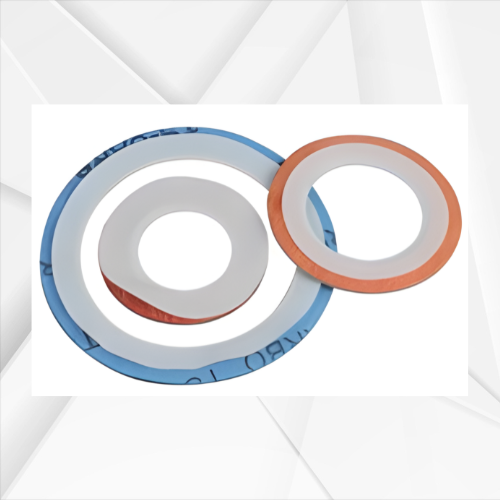

PTFE Envelope Gasket

Key Features of PTFE Envelope Gaskets

| Feature | Description |

|---|---|

| Advanced Construction | PTFE outer layer with soft insert (EPDM/Nitrile/CFS) ensures superior sealing and flexibility. |

| Chemical Resistance | Excellent resistance to aggressive chemicals, acids, and solvents. |

| Clean & Non-Contaminating | Suitable for applications requiring purity — ideal for food, pharma, and chemical industries. |

| Temperature & Pressure Stability | Performs reliably under varying temperature and pressure conditions. |

| Versatile Applications | Used in pipelines, heat exchangers, valves, and flanged joints across multiple industries. |

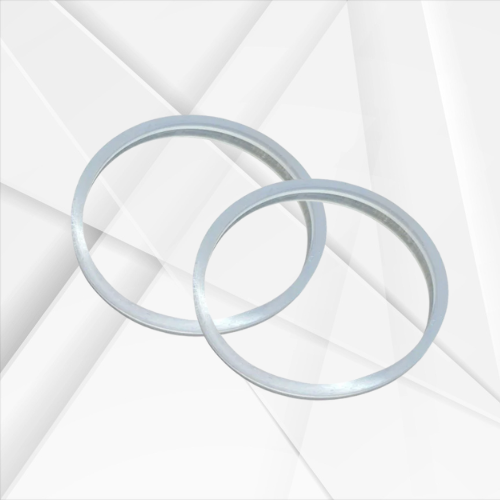

RTJ Ring Gasket

Key Features of RTJ Ring Gaskets

| Feature | Description |

|---|---|

| High-Strength Material | Made from premium metals such as Stainless Steel, Soft Iron, and Inconel for superior durability. |

| Pressure Handling | Designed for high-pressure and high-temperature environments with excellent sealing efficiency. |

| Accurate Machining | Precision-engineered for perfect groove alignment and leak-proof connections. |

| Standards Compliance | Conforms to API 6A, ASME B16.20, and ANSI B16.5 specifications. |

| Application Range | Widely used in oil & gas, petrochemical, refinery, and power generation industries. |

Chemical Sector PTFE Gasket

Key Features of Chemical sector PTFE Gaskets

| Feature | Description |

|---|---|

| Premium Material | Manufactured from 100% virgin PTFE, ensuring outstanding chemical and corrosion resistance. |

| Accurate Thickness | 1 mm precision thickness provides reliable sealing for tight spaces and smooth surfaces. |

| Thermal Stability | Performs efficiently under a wide temperature range without losing structural integrity. |

| Chemical Resistance | Unaffected by most acids, alkalis, and solvents — ideal for the chemical industry. |

| Application Use | Widely used in chemical plants, refineries, pharmaceutical processing, and fluid transfer systems. |

Petrochemical Sector PTFE Gasket

Key Features of Petrochemical sector PTFE Gaskets

| Feature | Description |

|---|---|

| Material Quality | Made from 100% virgin PTFE for superior chemical resistance and long service life. |

| Thickness & Precision | 2.5 mm uniform thickness ensures reliable sealing and dimensional stability. |

| Temperature Resistance | Performs efficiently under extreme temperature and pressure conditions. |

| Chemical Compatibility | Resistant to acids, alkalis, solvents, and corrosive gases — ideal for petrochemical applications. |

| Industrial Applications | Widely used in petrochemical plants, refineries, chemical processing units, and gas pipelines. |

Food industry PTFE Gasket

Key Features of Food Industry PTFE Gaskets

| Feature | Description |

|---|---|

| Food-Grade Material | Made from 100% virgin, FDA-approved PTFE for safe use in food and beverage applications. |

| Non-Stick & Hygienic | Smooth, non-porous surface prevents contamination and buildup of residues. |

| Chemical & Temperature Resistance | Excellent resistance to oils, fats, acids, and high temperatures. |

| Precision Thickness | 3 mm design ensures reliable sealing and easy installation. |

| Applications | Widely used in food processing units, dairy plants, beverage lines, and pharmaceutical systems. |

Silicone Rubber Gasket

Key Features of Silicone Rubber Gaskets

| Feature | Description |

|---|---|

| Premium Silicone Material | Manufactured from high-grade silicone elastomer for excellent flexibility and resilience. |

| Temperature Resistance | Performs efficiently in temperatures ranging from -60°C to +230°C. |

| Non-Toxic & Hygienic | FDA-approved and suitable for food, medical, and cleanroom applications. |

| Weather & Aging Resistance | Resistant to ozone, UV rays, and environmental exposure for long service life. |

| Versatile Applications | Widely used in food processing, pharmaceutical, electrical, and automotive industries. |

EPDM Rubber Gasket

Key Features of EPDM Rubber Gaskets

| Feature | Description |

|---|---|

| High-Quality Material | Made from premium-grade EPDM rubber for excellent flexibility and weather resistance. |

| Water & Chemical Resistance | Performs reliably against water, mild acids, alkalis, and steam exposure. |

| Durable & Resilient | 15 mm thick design provides strong compression and long-lasting sealing performance. |

| Temperature Stability | Maintains elasticity in temperatures ranging from -40°C to +120°C. |

| Applications | Used in plumbing systems, HVAC units, water treatment plants, and automotive sealing assemblies. |

Neoprene Rubber Gasket

Key Features of Neoprene Rubber Gaskets

| Feature | Description |

|---|---|

| Premium Material | Manufactured from high-grade Neoprene (Chloroprene) rubber for superior durability and flexibility. |

| Oil & Weather Resistance | Excellent resistance to oils, ozone, sunlight, and environmental conditions. |

| Durable Thickness | 2.5 mm uniform thickness ensures effective sealing and reliable compression. |

| Temperature Range | Performs efficiently between -40°C and +120°C without deformation or cracking. |

| Applications | Used in HVAC systems, marine, electrical, and industrial sealing applications. |

Useful Links:

- Sealing & packaging machines

- industrial flanges

- Instrumentation & Fittings

- forged pipe fittings

- fasteners

- Industrial Gasket

- Cable Lugs

- electrical components